Tunnel Washer

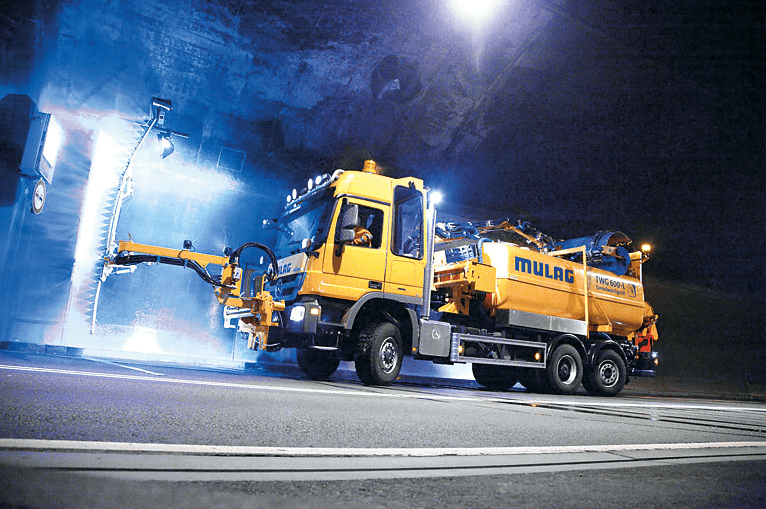

TWG 600-L

With the newly developed tunnel cleaner TWG 600-L, a cleaning system has been provided that not only washes the ceilings and walls of tunnel sections but also allows for efficient cleaning of niches and road surfaces.

It is equipped with a powerful high-pressure water pump with an input of 100 kW. At its maximum delivery rate, it distributes the contents of the sizeable 13,500-litre tank in about 35 minutes.

The three-section high-pressure spray bar, with its maximum width of 3.6 m, hydraulically adjusts to the contour of the surface to be cleaned. As a unique feature, it is continually adjustable in all three axles. It flexibly cleans walls, ceilings, the road surface adjacent to the vehicle, and the tunnel lights. Ultrasonic sensors help the operator keep the distance between the washing system and the surface to be cleaned. Each of the three spray tubes can be switched on and off individually and independently of the others. If necessary, the arm can also be used for left-hand operation.

The boom arm of the TWG 600-L can be extended up to 6 m to the side and 8.5 m in the vertical direction; it is mounted between the driver’s cab and the water tank. The key benefits of this arm design are the hydraulic lateral shift of the boom system, as well as the telescope in the first arm. All functions can be controlled hydraulically from the operating panel in a clear view of the operator.

The three-section high-pressure road cleaning bar with a maximum width of 5.1 m, designed in three sections, is attached at the front. The key feature of this device is the central telescopic extension that can be moved forward by 1.4 m, giving the driver sitting in a regular work position a good view of this additional working attachment. The two outside spray bars can be lifted by 0.35 m for optimum sidewalk cleaning. Each of the three spray tubes of the road washing bar can likewise be switched on and off independently. Furthermore, the entire front-mounted cleaning system offers a time-controlled automated park-in function.

At the rear of the vehicle, a sewer flushing unit is mounted. It has a hydraulically driven hose reel with 120m of high-pressure hose. The hose reel has a 90-degree swivel range, a continuous drive, and a meter counter to indicate the length of the uncoiled hose. The water pressure of 105 bar at 230 l/min is powerful enough for demanding sewer cleaning jobs. The device is entirely controlled via remote control. The professional truck-mounted tunnel washer furthermore offers a high-pressure hand lance mounted at the rear of the vehicle, various boxes, storage compartments and shelves for tools and accessories, as well as a radio-controlled flashing LED arrow – an indispensable road safety feature – and a rear-view camera.

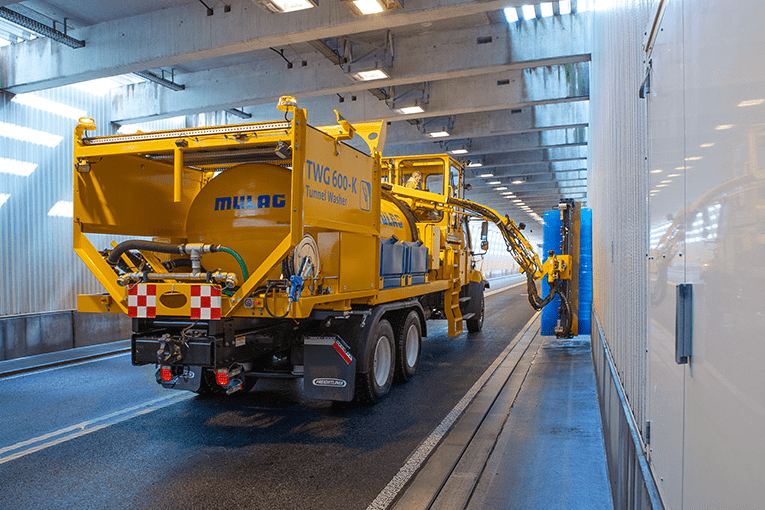

TWG 600-K

The TWG 600-K is a flexible tunnel cleaning system with a carrier vehicle independent drive that can be mounted on all standard trucks of a specific payload and body length.

Mounting and dismounting are quick and easy via container-type twist-locks. No further equipment is necessary as the unit has its support legs.

All functions of the TWG 600-K are controlled from the integrated operator’s cabin. The operator is permanently connected to the driver via voice radio.

The long reach of the boom arm and the implements equipped with modern sensor technology, such as the high-pressure flush bar and the tunnel washing brush, enable effective and thorough tunnel cleaning.

- Separate implement drive by on-board motor

- Operator’s cabin with panoramic window

- Large water tank

- Boom arm with a high-pressure flush bar or tunnel-washing brush

- High-pressure hand lance at the rear

- Various storage options, such as tool and material boxes

- Easy mounting and dismounting with container-style twist-locks

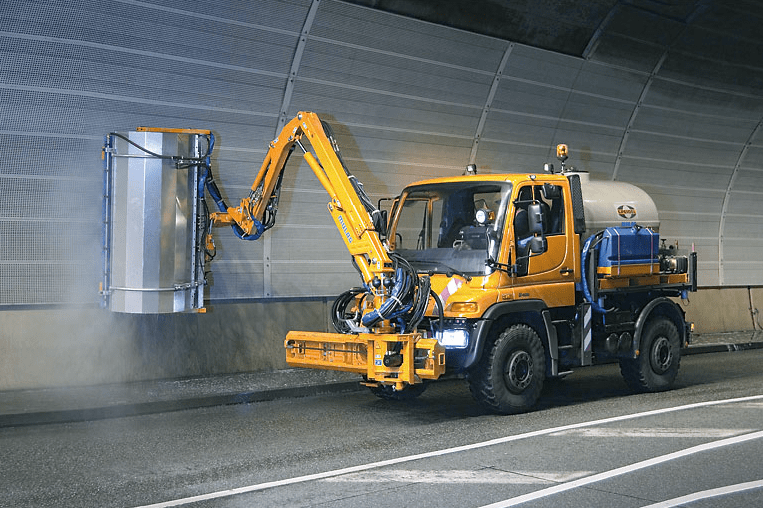

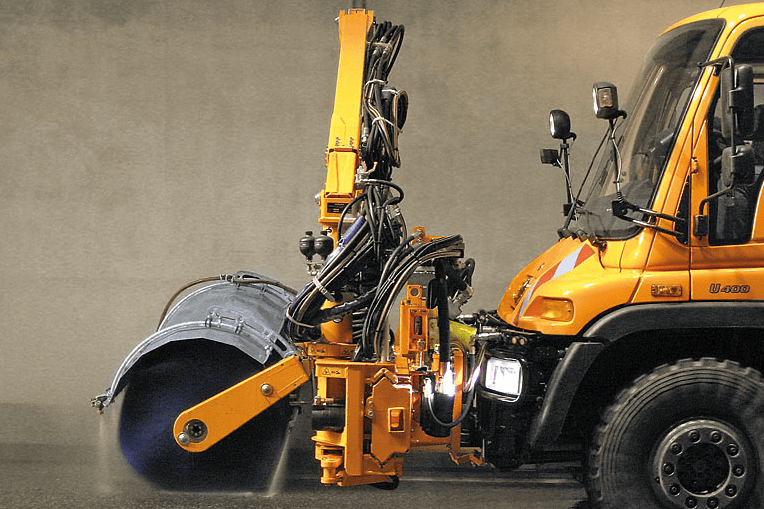

MFK 500-T

The tunnel cleaner MFK 500-T excels with innovative options such as a convenient detergent dosing system and very efficient high-pressure cleaning equipment.

Based on the successful MFK 500 front arm series, the tunnel cleaner was adapted to meet the unique requirements of professional tunnel maintenance: a standard telescopic arm enables significant cleaning heights, and the lateral shift makes it easier to adjust the equipment to the conditions in the tunnel. The transport position of the component in front of the vehicle offers an easy park-out and park-in function even in narrow tunnel cross sections. Through the hydraulic swivelling device of the brush, the tunnel cleaner is ready for operation swiftly.

Contact Us

25450 80th Ave.

Langley, B.C.

V1M 3M9

Phone: (604) 888-6228

Fax: (604) 888-3861